Bal-tec™ Home How Kinematic Couples Can Be Used in Metrology

How Kinematic Couples Can Be Used in Metrology

The unparalleled repeatability for location and the lack of dimensional distortion of the test part due to the almost zero force required to secure the part in a kinematic coupling, makes these devices the obvious choice for mounting test parts and tooling for inspection applications.To get the most from kinematic couples, some very simple principals must be understood and applied.

To tie down a part so that it can not move at all, requires that everyone of the six potential degrees of freedom must be constrained. A part can move forward and back. It can move to the left and to the right, and it can move up and down. These are the three degrees of linear freedom. A part can also rotate around, each one of these three linear degrees of freedom. The part can “Pitch” around the forward and back axis. It can “Yaw” around the up and down axis and it can “Roll” around the left to right axis.

To be truly kinematic, the couple’s contact with the part must be restricted to points of contact, not lines or areas of contact. Of all the mistakes that can be made in the accurate location and relocation of the test part kinematically, it is using anything but points of contact. The next most common problem is using more than, or less than the required six points of constraint

By far the best and most widely used point of contact for kinematic couplings is a precision, hard, stainless steel ball. These devices give the highest quality contact with extremely good wear properties. By attaching three precision balls temporarily to the test part, the best possible method of locating the part for inspection is achieved. A precision ball with a flat may be temporarily attached to the test part with quick setting Krazy Glue™. The glue residue can be removed with Acetone (check the M.S.D.S. for safely using Acetone).

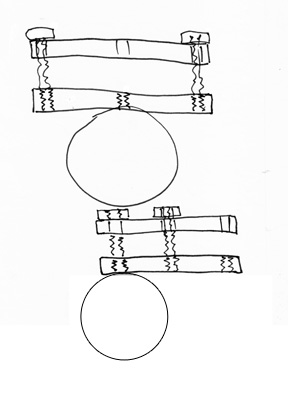

A threaded ball may be temporarily attached to the test part with a threaded fastener. A truncated and threaded ball may be temporarily attached to the test part with our bar clamp, part number BC-2 or BC-3.