Bal-tec™ Home The Male Cones

The Male Cones

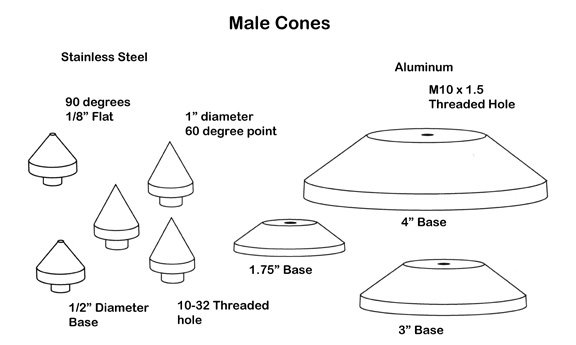

When the surface of a Male Cone is brought into contact with the circle formed at the intersection of a hole and a plane, three degrees of test part freedom are constrained. Two side by side Cones will form an excellent Vee-block to restrict two degrees of test part freedom. A full set of ten Male Cones (Part #40060) consists of two pieces each of the five standard designs. The smallest Male Cone (Part #40010) has a 60 degree included angle so that it is compatible with the standard shaft centers. It starts at a sharp point and goes up to one inch (2.54 cm) diameter. This small Cone is made of hardened stainless steel and the Cone is precision ground. This smallest of the Conical component uses the standard one half inch (1.27 cm) diameter boss with a #10-32 hold down thread to form a high load carrying joint. Two of these Cones mounted on "High Precision Jacks" (Part #30010) provide an excellent method for mounting a shaft on centers.

Another small diameter hardened stainless steel Male Cone (Part #40020) has a 90 degree included angle. The 90 degree angle starts at a one eighth inch (.32 cm) diameter flat tip and goes up to the full one inch (2.54 cm) diameter. This Male Cone is precision ground. It has the standard one half inch (1.27 cm) diameter boss with a #10-32 hold down to provide high load carrying capacity. The three larger Cones are made of aircraft quality high strength aluminum alloy that is hard surfaced for wear resistance. The smallest Aluminum Cone (Part #40030) starts at five eighths of an inch (1.6 cm) diameter and goes up to one and three quarters inch (4.5 cm) diameter. It is three quarters of an inch (1.9 cm) thick. The next larger Aluminum Cone (Part #40040) starts at one and one half inch (3.8 cm) diameter and goes up to three inches (7.6 cm) diameter. It is seven eighths of an inch (2.2 cm) thick. The largest of the Aluminum Code ( Part #40050) starts at two and one half inches (6.35 cm) diameter and goes up to four inches (10.2 cm) in diameter. It is one inches (2.54 cm) thick.

These larger Aluminum Cones have a 90 degree included angle for long wear and good load carrying capacity. It should be noted that there is a small overlap between the individual diameters of the Cones so that there is no chance of a gap in the hole sizes that can be accommodated. The three larger Male Cones have an M10 × 1.5 threaded hole all the way through the center of the part to provide for solid attachment to the mating fixture building component. The remaining cylindrical diameter at the bottom of these Cones can be used as a cylindrical location datum. When any one of these Aluminum Cones is turned up side down they provide an excellent flat location table. The four inch (10.2 cm) diameter Cone has two additional M10 × 1.5 threaded holes in the flat location table. The four inch ( 4.0", 10.2 cm ) diameter Cone has two additional M10 × 1.5 threaded holes in the flat back side to provide extra utility for location and clamping.