Bal-tec™ Home CMM Clamping Devices

CMM Clamping Devices

All of our Ball Bar clamping devices are designed to be very quick acting, so that only brief hand contact is required when loading them; and no contact is required when changing the angle, the position, or the elevation of the Ball Bar.

The Crown

The Crown, Part Number AN-CR is a small lightweight aluminum device that is designed to hold calibration equipment on very small Coordinate Measuring Machines. The overall height is four and one half inches (114mm). It has a three inch (76mm) diameter base, or foot. There is a counterbored hole in the center of the base that will accommodate either a three eighths of an inch or a ten millimeter socket head cap screw, to hold the Crown down on the C.M.M. table or other mounting devices. The center line or pivot point of this device is three inches (76mm) above the base. If there are threaded holes in the C.M.M. table, the Crown can be screwed directly on to the table. This product is compatible with many of our C.M.M. mounting devices. It will screw directly to the top bulkhead of any of the "Anchor".

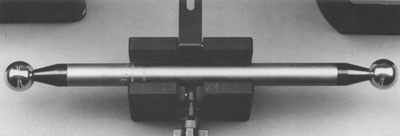

The Dual Ball Bar Clamp

A take off on the single Ball Bar for interim evaluation is The Ball Bar Kit where a special double Ball Bar clamping device (Part # FS-2BB) is substituted for the standard single bar clamp. The two Ball Bars are usually one short 300mm (11.8 inches) and one long 600 mm(23.6 inches) or 600mm and 900 mm (35.4 inches), sphere center to center length.

The extra data points collected from the double Ball Bar device tend to show up short, wavy errors. The length of the Ball Bar or Ball Bars chosen for the interim check should be as long as possible but short enough to allow the holding device to be rotated on the C.M.M. table to form the four sides of a cube.

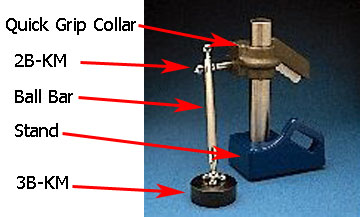

The Quick Grip Collar for the Stand

A conventional free standing Ball Bar (Dumbbell) will bend when the contact force of the measuring probe is applied to it. The longer the Ball Bar (Dumbbell), the greater the bending. With all of the automatic error correcting computer power, it should be easy enough to compensate for these Ball Bar (Dumbbell) deflections. However, these corrections turn out to be a good deal more complex than they first appear.

The resulting deflection of the Ball is a rather complex vector function of gravitational sag, some simple bending and a large twisting moment. This is all complicated by the fact that there is no deflection at all on the very ends of the Ball Bar (Dumbbell). The end result of this complexity is that the C.M.M. and its software see two much smaller diameter spheres with the distance between their centers much further apart then the true dimension.

IT'S FAST - Just squeeze the Quick-Grip handle with your right hand and you can zip the two ball kinematic coupling up or down on the rugged two-inch diameter hard surfaced column. At the same time your left hand can propel the base around the table through a conveniently located handle. Nothing to tighten, nothing to loosen, no screws, no tools, just squeeze the grip; and in three seconds, the Ball Bar (Dumbbell) is in a new position and ready to measure again.

In addition to the ultra-fast positioning capability of the Quick Grip Stand, it all but eliminates the main error associated with Ball Bar (Dumbbell) evaluation. This error is a deflection of the target ball caused by a bending and deflection of the Ball Bar (Dumbbell) and the vertical support post by the contact force of the measuring probe. It eliminates the problem by supporting both ends of the Ball Bar (Dumbbell) by very rigid structures which eliminate the bending and twisting movements.

The Quick-Grip Stand is supplied with a hold-down device that consists of a long, threaded shaft which extends all the way down through the length of the vertical column and screws into the CMM table, thus removing even the smallest tendency of the stand to tip when making extremely critical evaluations.

Small Ball Bar Clamp

This small Ball Bar Clamp, Part Number FS-1BB-S is intended to hold inspection devices on very small Coordinate Measuring Machines. The three-quarter inch ( 3/4", 19mm ) diameter tube of the Ball Bar or cylindrical diameter of the gage block is held in the vee block of the clamp.

Part Number GB-4 will meet the requirement of measuring a gage block which is now required by the revised ANSI B89.4.1-1997 specification for "Performance Evaluation of Coordinate Measuring Machines". This very small Ball Bar Clamp is only two inches (2.0", 50.8mm) wide, two inches (2.0", 50.8mm) thick and three inches ( 3.0", 76.2mm ) high.

Important Note: If the ball bar you need is 100 or 200 millimeters in length, you will need a small ball bar clamp to hold it. The distance between the balls on these ball bars will not clear the clamping fixture itself.

The Tri-mount Collar for Ball Bar Stands

The Tri-mount TM Ball Bar collar is a recent improvement in the tools for Coordinate Measuring Machine evaluation. The fundamental design of the Tri-mount allows it to hold three or more separate Ball Bars all at the same time. It is machined to form a collar that wraps around the vertical post of the stand. A slot is used to lock this rear block in place. It is capable of holding as many as three Ball Bar Clamps at the same time, also referred to as the front blocks. Using three double Ball Bar clamps, the Tri-mount could potentially hold as many as six Ball Bars.

With one Ball Bar held vertical, one held horizontal and one held at an angle, all of the twenty positions specified in the ANSI B89.4.1-1997 standard can be achieved. A unique feature of this new device is that it totally eliminates any hand contact with the Ball Bar (Dumbbell) by the calibration technician. This is especially important because all Ball Bars are rather long devices which make them very sensitive to temperature change.

The location ports on the Tri-mount will accept the Single Ball Bar clamp (Part #FS-1BB), the Dual Ball Bar Clamp (Part # FS-2BB), the Small Ball Bar Clamp, (Part #FS-1BB-S) or any length of the Way Out Ball Bar Supports.

The front block is fitted with a long Vee Block which is used to securely hold the Ball Bar (Dumbbell). The front block will allow the Ball Bar (Dumbbell) to rotate a full 360° parallel to the vertical post, allowing a full range of positioning. Both of the blocks are hard anodized for wear resistance.

To install a Ball Bar in the free standing Ball Bar clamping device, first loosen the cap screw and set the clamp horizontal, with the Vee-Block up. Next tighten the cap screw to secure the clamping device. Now loosen the four spoke locking knob and flip the clamping bar back. Quickly place the Ball Bar in the Vee-Block and flip the clamping bar forward, then tighten the four spoke locking knob

This new approach provides an economical artifact that is 100% compatible with all of our Ball Bar clamping devices. This simple approach allows even the shortest Ball Bar (Dumbbell) to be held on any of our standard Heavy Duty stands or any of the Anchor systems.

The Way Out Ball Bar Support Rail

This device is a very rigid Tee shaped aluminum rail. It Kinematically supports the Ball Bar balls or as pictured here with the Cantilevered Ball Bar. This added support virtually eliminates any bending of the Ball Bar. In use, The Way Out Ball Bar Support is attached to the Tri-mount collar on the Heavy Duty Stand or the Anchor. A socket head shoulder bolt passes through the center of the aluminum rail. The desired angle is set and the Way Out Support is clamped down.

Clamping Device and Way Out Rail Pricing

See the CMM Prices page for complete pricing.