Bal-tec™ Home Flexural Springs for Kinematic Preload

Flexural Springs for Kinematic Preload

| Downloads | ||

|---|---|---|

| Solidworks | IGES | |

Helical Springs

Using a helical spring to provide a preloading force will always produce some off axis or torque loads on the Kinematic preload. When you stretch the spring it will uncoil slightly. If you stretch a spring with the ends tethered, it will impart a rotary stress to the structure.

Belleville Springs

Belleville spring washers are far superior to coil springs, if they have a precisely machined annulus on the inside and outside contact edges, but the force applied by these springs is in the wrong direction. They are pushing things apart, instead of pulling them together. Building a mechanism that will reverse the direction of the force will leave large mechanisms protruding from the structure. This mechanism will not be any where near the axis of the kinematic coupling, so there will be with off axis stresses.

Flexural Springs

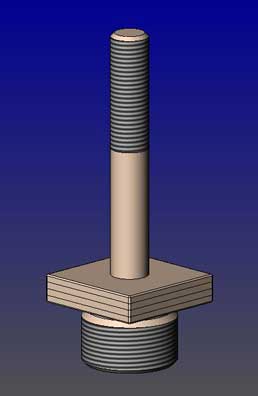

The straight forward solution to the dilemma of spring preloading kinematic systems is to use a three degrees of freedom flexural spring. We developed this device for a NIST project. It consists of a square block of spring metal sliced almost through in four orthogonal planes. This leaves the equivalent of a dual compound flexure. Any off axis tendencies that develop as the flexure is accordioned will be equal and opposite in direction with a resulting off axis force that is zero. Our standard, off the shelf device, Part Number SF-1 has a five eights of an inch diameter threaded boss ( 5/8", 0.625 inch ) [15.875mm] with eighteen ( 18 ) threads per inch on one end, and a long one quarter inch diameter (0.250 inch ) [6.35mm] with twenty ( 20 ) threads per inch on the other.

The SF-1 was designed and developed specifically for use with our preassembled kinematic platforms 3-inch by 3-inch and 6-inch by 6-inch. The 5/8 x 18 threads will screw directly into the If the specifications for this specific part do not fit your needs, we will design and build a custom device that will. By using the spherical tilt ( our part number, 75-ST-270, the thrust bearing and the clocking nut, our part number, 250-20-CN ) a spring preloaded device that is free of any off axis stresses is achieved. The SF-1 IS accessorized with the Clocking Nut, the spherical tilt, and the thrust bearing.

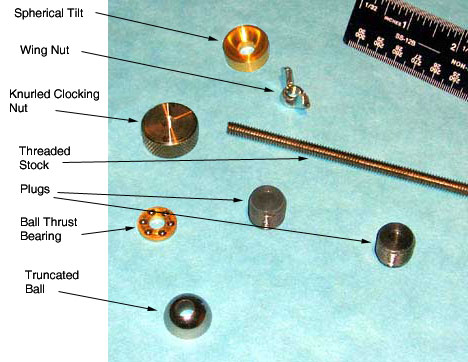

The Flexural Spring is our part number SF-1 is sold as a kit which includes: the flexural Spring, a Plug, a Spherical Tilt, a Truncated Ball, a Ball Thrust Bearing and a Clocking Nut. The assembly instructions follow for the Flexural Spring and a 3 X 3 Kinematic Platform to achieve a vertical mounting position.

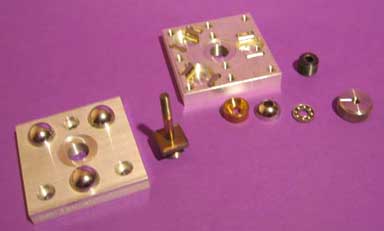

Begin with the Bottom Platform (1) and screw the Flexural Spring (2) into the center of the plate. Take the top platform (3) and screw the Plug (4) into the center. Fit the top plate over the extended end of Flexure (2) and fit the two plates together.

Next place the spherical Tilt (5) over the extended flexure (2) with the spherical cup facing up. Fit the Truncated Ball (5) into this cup so that the top is now the flat face of the truncated ball. Add the Ball Thrust Bearing next (5) and finally the Clocking Nut (5). Tighten the clocking nut to finish the setup.