Bal-tec™ Home Making the Roundness Measurement of Our Gage Balls

Making the Roundness Measurement of Our Gage Balls

When measuring the sphericity of our Gage Balls, we don't want whistles and bells or smoke and mirrors to mandate the nature of the data reported by the inspection equipment. What we want is a straight forward measuring machine, that presents transparent evaluations of the part's quality with an accuracy that is directly traceable to a natural phenomena.

We feel comfortable when our final evaluation is derived using the speed of light at a temperature determined by the melting point of gallium metal with output data that is confirmed by the redundancy of reversal technology. The "Talyrond" measuring system, is a circular geometry measuring machine that comes as close to these requirements as any machine that has ever been built.

The rugged "C" frame construction of the Talyrond virtually eliminates any short term temperature and or mechanical variations. The huge cast iron frame of this machine provides both mechanical stability and a huge heat sink that dramatically slows any dimensional changes due to temperature variations, so that any measurable error will occur long after our roundness evaluation is complete.

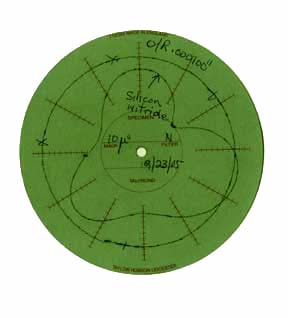

This machine provides output data in the form of a permanent polar chart recording that can be supplied as documentation to the customer with the parts, or it can be transmitted to the customer electronically.

See also, our page "Measuring Sphericity."