Bal-tec™ Home Monolithic Trihedral

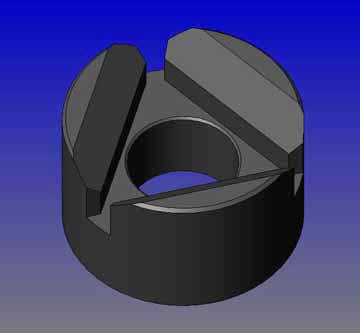

Monolithic Trihedral — Kelvin Clamp

| Downloads | |||

|---|---|---|---|

| Part # | Solidworks | IGES | |

| TRH-75-SM | |||

| TRH-2000-SM | |||

We are now producing two standard sizes of the Monolithic Trihedral kinematic component. They are designed for a surface mount. This trihedral is frequently referred to as a Kelvin Clamp. These devices are constructed from a very fine-grain, high-carbon, high-chrome stainless-steel that is through-hardened to 58-HRC minimum. The typical application for this component is to constrain three degrees of freedom in a Kelvin-type kinematic-coupling. This devices is the technically-correct approach for this coupling, whereas the commonly thought-of conical-cups are a very low quality over-constrained approach to achieving this coupling.

In this application, the Trihedral is used in conjunction with a vee-block and a flat surface, combined with three balls or spherical surfaces to complete the coupling. The smallest of these off the shelf Monolithic Trihedrals is our Part# TRH-75-SM. It is used in conjunction with our VB-75-SM or VB-75-CPM (surface or post-mounted Veeblock) and flat a component (see our literature for design criteria and price). This combination can be used with balls ranging from 5/8-inch (.625", 15.9mm) to 1.0 inch (25.4mm) diameter.

This device has a three-eighths-inch-sixteen threaded hole going through the center (3/8”, .375”, 9.525mm). This facilitates using our standard 3/8-inch rare-earth magnet (part # 375-24-MG-N) to provide an axial preload. The largest of these off the shelf Monolithic Trihedrals is our Part# TRH-2000-SM. This is used in conjunction with our VB-2000-SM or VB-2000-CPM (Vee Block) and flat component (see our literature for design criteria and price). This combination can be used with balls ranging from 1-1/4 inch (1.25”, 31.75mm) diameter to over 2-inches (50.8mm) diameter. This large-size trihedral has a unique feature, there is a one inch diameter (25.4mm), threaded-hole through the center of the base. This facilitates using our standard 1-inch by 14-thread (25.4mm) rare-earth magnet (Part #1000-14-MG-N) to provide a preload (see our literature for design criterion and pricing). The hole through the center of this large trihedral allows for a payload to hang with the load-carrying shaft passing through the center hole.

Some reasons for using the Kelvin-type kinematic coupling instead of the much simpler and less expensive Maxwell system consisting of three vees and three balls, is in the case that one single point on the payload must stay in exactly the same location during temperature changes (the point held by the Trihedral). Another is that rotary-adjustments need to be made around one specific point (the point held by the Trihedral). This is a typical requirement in optical systems where a laser or other light source must be accurately and precisely pointed or directed to the optical-axis of a system.

The Kelvin kinematic system is excellent for vertical and other off-axis kinematic couplings (see 'Vertical Kinematic Coupling' in the 'Kinematic Encyclopedia' on our www.precisionballs.com website.

One last design trick: the simple combination of a Trihedral and a Veeblock form an excellent Kinematic hinge that will accurately constrain five degrees of freedom, leaving one single degree of rotation.